As mentioned in our previous blog post, the industries using instrumentation valves and fittings are evolving, which has paved the way for substantial growth in the instrumentation market. Each industry often uses different instrumentation products, has different applications and must adhere to specific industry standards. The following are some notable examples:

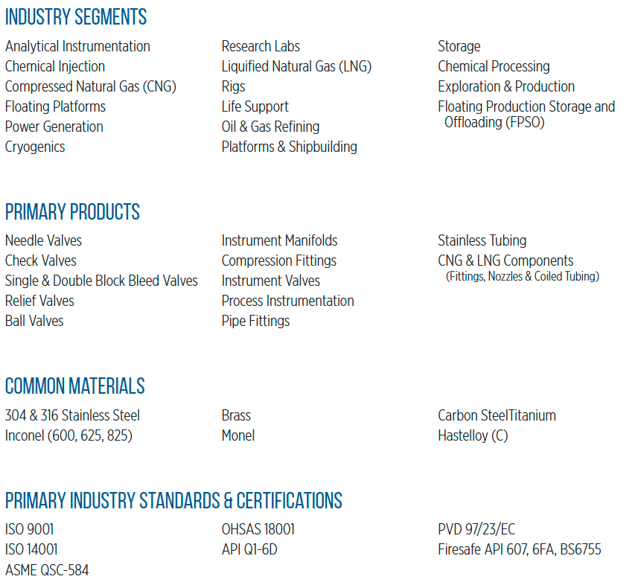

Chemical & Petro-Chemical Processing

Chemical processing is perhaps the broadest industry, covering many segments. Instrumentation fittings and valves are used in all of the chemical and chemical processing industry’s applications, from research labs, production processes to pilot plants.

Oil & Gas: Exploration, Offshore, Onshore, Refining & Production

Oil & Gas: Exploration, Offshore, Onshore, Refining & Production

Perhaps the 2nd broadest industry in its coverage of a variety of industry segments for instrumentation applications is oil & gas. Instrumentation in oil & gas is used in exploration, upstream and downstream applications, deep hole drilling, chemical fracturing, CNG & LNG storage and transfer, natural gas and more.

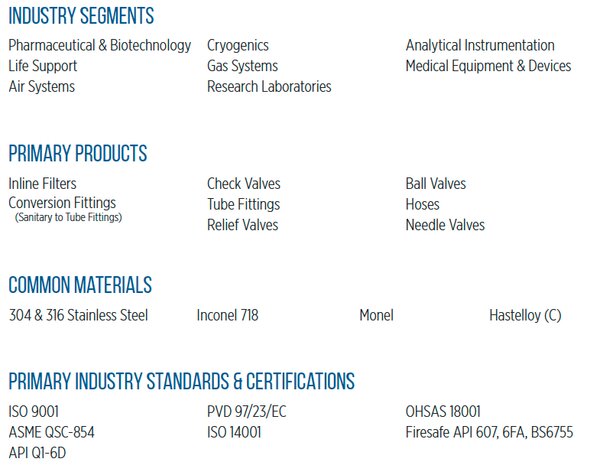

Medical, Pharmaceuticals & Bio-Technology

The medical equipment, device and pharmaceutical markets are major users of instrumentation components. There is a wide variety of instrumentation used in medical equipment and devices, as well as pharmaceutical processing facilities and equipment.

With the rapid spread of the coronavirus, healthcare and pharmaceuticals saw an increased demand for the production of critical medical technologies required to safeguard and eventually cure COVID patients and inoculate for the disease. With a pandemic of this magnitude and lifecycle, there will be increasing demands for research and development to be prepared for any potential future outbreaks. Instrumentation components play a significant part in the research, development and manufacturing of advances in medicine and medical devices-- and this demand will continue for years or decades to come.

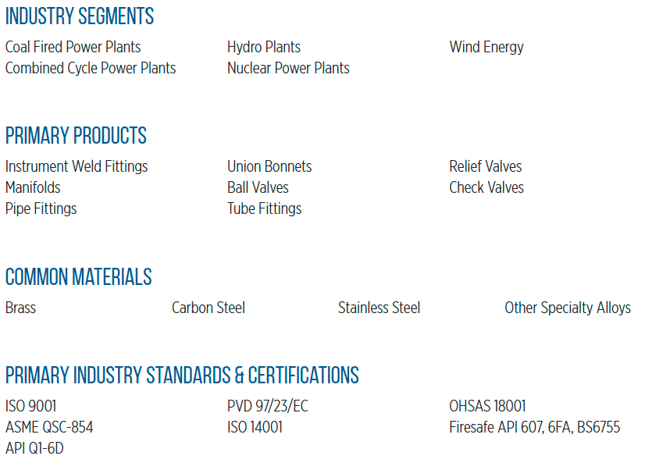

Power Generation/Power Plants

There are many applications for instrumentation fittings and valves in the control processes of power plants, including boilers, exhaust gas boilers and incinerators, turbine generators, condensers, material handling systems and more.

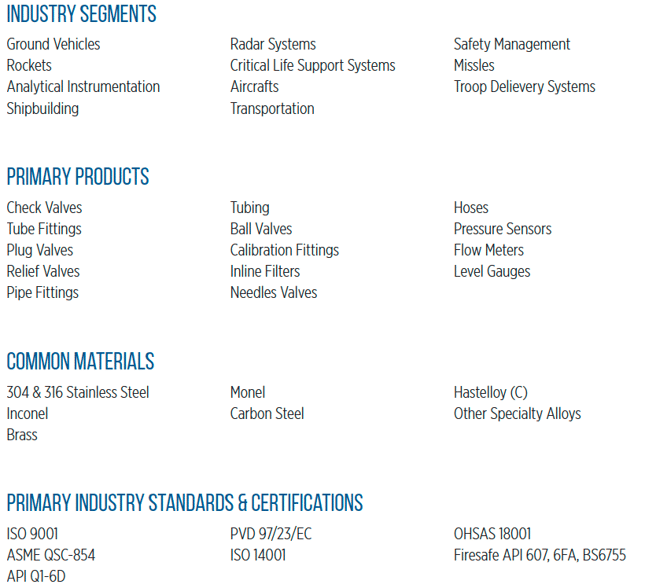

Defense: Aerospace, Navy & Military

Instrumentation fittings and valves are used in every segment of aerospace, navy and military. To supply product for the defense industries, manufacturers must meet stringent standards including ‟AS” and Nadcap accreditation for fluid system components. Suppliers must be certified to AS9100D, including all of the requirements of ISO 9001:2015, to manufacture fluid system fittings for the aviation, space and defense industries. They also require conformance to other specific certifications for individual applications. Additionally, accreditation with the National Aerospace and Defense Contractors Accreditation Program (Nadcap) for fluid distribution systems is required to be placed on the Qualified Manufacturer Listing (QML), recognizing suppliers of these products to the military and aerospace industries.

Each of these industries has a critical use for Instrumentation fittings, so knowing how to select the proper fitting for each of these applications is critical. Our next blog will break down the selection of primary instrumentation components.

Since you seemed interested in our instrumentation content, check our Free BluePrint over Installation Applications & Industries for Instrumentation Fittings.

Click below to browse our other Instrumentation content.

.png)