Alloys vs. Superalloys (HPAs High Performance Alloys)

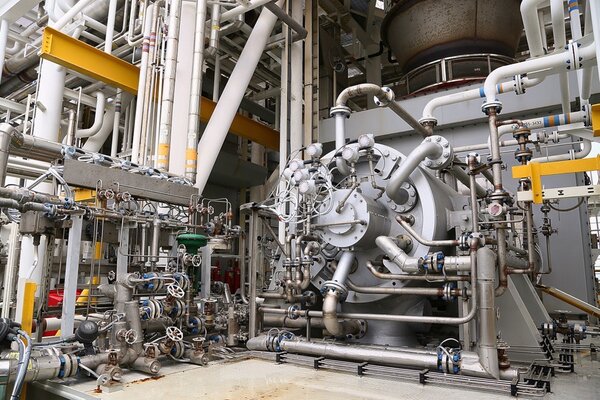

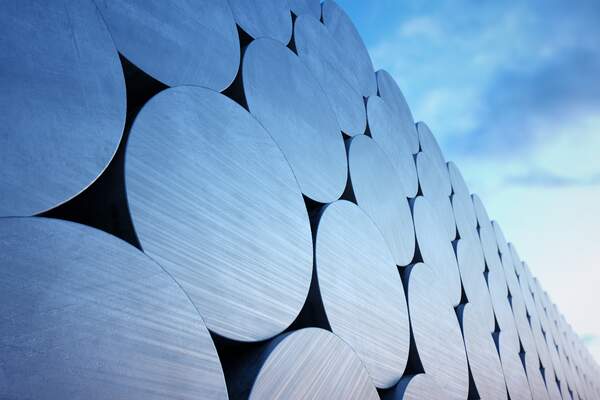

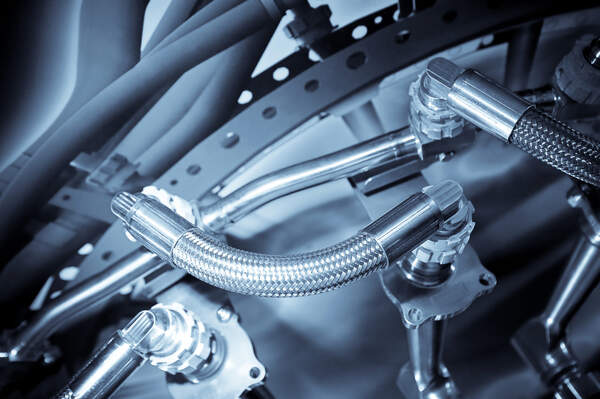

Alloys are metallic substances composed of two or more elements, as either a compound or a solution. The most common metal alloys in industrial applications are carbon steel and brass, an alloy of copper and zinc. However, special alloys are typically referred to as Superalloys or High Performance Alloys, which are made to withstand high temperatures, high stresses, and often highly oxidizing atmospheres with a resistance to corrosion or oxidation. Superalloys are nickel based with several key characteristics, including excellent mechanical strength, resistance to thermal creep deformation, and good surface stability. The development of superalloys has primarily been driven by the aerospace and power industries. Widely used superalloys are Hastelloy®, Inconel®, Invar ®, and Monel ®.