Not Too Early, Not Too Late - Just Right!

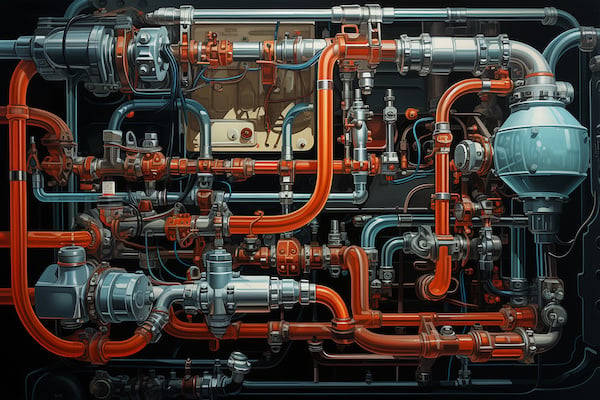

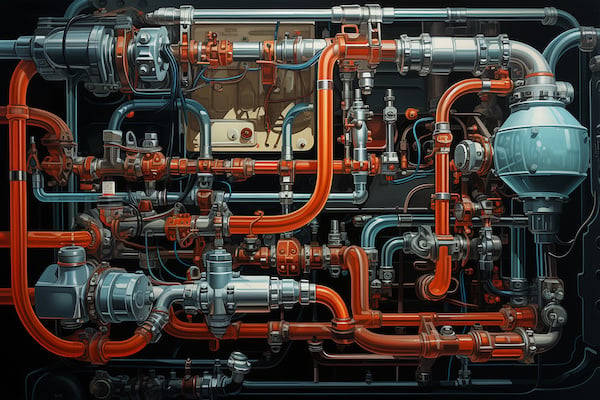

Hydraulic systems do not adhere to a specific timeframe for fluid replacement, in contrast to other machinery. Changing the fluid when you feel it is time can harm your equipment, requiring repair time and money. Instead, watch for specific indicators that signal it's time to change your hydraulic fluid.

Hydraulic fluid change or hydraulic flush?

Hydraulic fluid change

There is a big difference between replacing the fluid and flushing the entire system. To change the hydraulic fluid, drain the old liquid and refill it with fresh fluid. While it can be time-consuming, this is important in keeping the machine healthy. It would help if you also replaced the filters before adding in new fluid.

Hydraulic flush

A hydraulic flush helps move contaminants out of the system. The best method for deciding when to change your hydraulic fluid is to perform an oil analysis. This helps you ensure you change the hydraulic oil only when it's really needed... Not too early, not too late- just right!

In most scenarios, a fluid change will be sufficient. However, it is sometimes needed to purge the entire system. Some examples of when it is necessary to perform a hydraulic flush are when:

There is a big difference between replacing the fluid and flushing the entire system. To change the hydraulic fluid, drain the old liquid and refill it with fresh fluid. While it can be time-consuming, this is important in keeping the machine healthy. It would help if you also replaced the filters before adding in new fluid.

Hydraulic flush

A hydraulic flush helps move contaminants out of the system. The best method for deciding when to change your hydraulic fluid is to perform an oil analysis. This helps you ensure you change the hydraulic oil only when it's really needed... Not too early, not too late- just right!

In most scenarios, a fluid change will be sufficient. However, it is sometimes needed to purge the entire system. Some examples of when it is necessary to perform a hydraulic flush are when:

- The machine is new.

- It recently had maintenance.

- It has not been used for some time.

- There was a significant breakdown.

- The hydraulic fluid deteriorated.

When to replace hydraulic fluid

There are a few situations where replacing your hydraulic fluid is essential. The primary reasons for hydraulic fluid failure are excess heat, contamination and the fluid’s degradation over time.

Excess Heat

Fluid degrades if it becomes too heated. Most of the time, you can tell it got too hot because the color changes and the scent is off. Usually, figuring this out can be done without the time and money of a fluid sample analysis. Exposure to very hot conditions will also accelerate the fluid's degradation.

Contamination

In the context of needing to replace your hydraulic fluid, contamination refers to more impurities in the fluid than your system's filtration can adequately remove. Typically, this particle contamination event overwhelms the system's onboard filtration capabilities.

But contamination also applies to circumstances where foreign substances mix into the fluid, such as adding water or accidentally topping out your hydraulic reservoir with the incorrect type of fluid. These contaminated fluids can damage hydraulic components and lead to system failures.

Degradation

A fluid analysis is necessary to determine if your system’s fluid is degraded. This happens because oxygen eventually interacts with the oil's hydrocarbon molecules, causing a chain reaction. This activity causes several evident symptoms, including varnishing, sludge and darker oil. The presence of residual air, increased viscosity and enhanced foaming are a few less visible conditions.

If the machine operates in a very hot or harsh environment, this process could happen faster; so, you might have to change it more often if it gets hot. Looking for signs of oxidation and analyzing fluid samples periodically can help you identify degradation issues before they cause damage to the hydraulic system. Replacing degraded fluid promptly will extend the life of your hydraulic machinery.

Excess Heat

Fluid degrades if it becomes too heated. Most of the time, you can tell it got too hot because the color changes and the scent is off. Usually, figuring this out can be done without the time and money of a fluid sample analysis. Exposure to very hot conditions will also accelerate the fluid's degradation.

Contamination

In the context of needing to replace your hydraulic fluid, contamination refers to more impurities in the fluid than your system's filtration can adequately remove. Typically, this particle contamination event overwhelms the system's onboard filtration capabilities.

But contamination also applies to circumstances where foreign substances mix into the fluid, such as adding water or accidentally topping out your hydraulic reservoir with the incorrect type of fluid. These contaminated fluids can damage hydraulic components and lead to system failures.

Degradation

A fluid analysis is necessary to determine if your system’s fluid is degraded. This happens because oxygen eventually interacts with the oil's hydrocarbon molecules, causing a chain reaction. This activity causes several evident symptoms, including varnishing, sludge and darker oil. The presence of residual air, increased viscosity and enhanced foaming are a few less visible conditions.

If the machine operates in a very hot or harsh environment, this process could happen faster; so, you might have to change it more often if it gets hot. Looking for signs of oxidation and analyzing fluid samples periodically can help you identify degradation issues before they cause damage to the hydraulic system. Replacing degraded fluid promptly will extend the life of your hydraulic machinery.

Conclusion

Understanding when to change your hydraulic fluid is crucial for keeping your machinery in good shape and avoiding costly repairs. Regular fluid analysis can help determine if your fluid has become contaminated, overheated or degraded over time. Replacing hydraulic fluid is usually sufficient, but a full system flush may be needed if contamination occurs, or significant repairs are done. With some attentiveness to the signs of deteriorating hydraulic fluid, you can help your hydraulic system run smoothly for years.

Learn about four considerations for safe hydraulic maintenance in this BluPrint:

Sources:

.png)