It’s a fact — every day we use, or even depend on, something powered by hydraulics. Hydraulic systems and components are in our cars, elevators, snowplows, bakeries, gas pumps and even desk and barbershop chairs. It’s true in the current industry 4.0 environment that digital technology powers almost everything. However, we often overlook that digital technology powers the hydraulics that do the “heavy lifting.”

6 Major Industries that use Hydraulics: Where and Why

Whether you’re taking off or landing in an airplane, riding your favorite roller coaster, battering the suspension in your 4x4 while driving off road or even drinking a beverage from a bottle or can, it couldn’t be done without hydraulics. Let’s look at some of the major applications where hydraulics are used and why.

Automotive

Passenger cars and trucks rely heavily on hydraulic systems and must meet SAE Standards. For example, the most important component in an automobile is the hydraulic circuit that controls the brakes. If you’ve seen a movie about mobsters, you might notice the bad guys don’t cut the good guy’s radio wires-- they cut his brake lines. You likely will not get very far with a clogged fuel line, flat tire or broken gas gauge. However, you’ll be much better off than experiencing a loss of brakes.

Hydraulics are also found in the suspension, power steering systems and even windshield wipers. There are multiple hydraulic fittings and other components in automobile applications, such as:

- AN fittings

- Flow control/excess flow valves

- O-ring face seal fittings

- Tube fittings, adapters, and many more

Aircraft & Aerospace

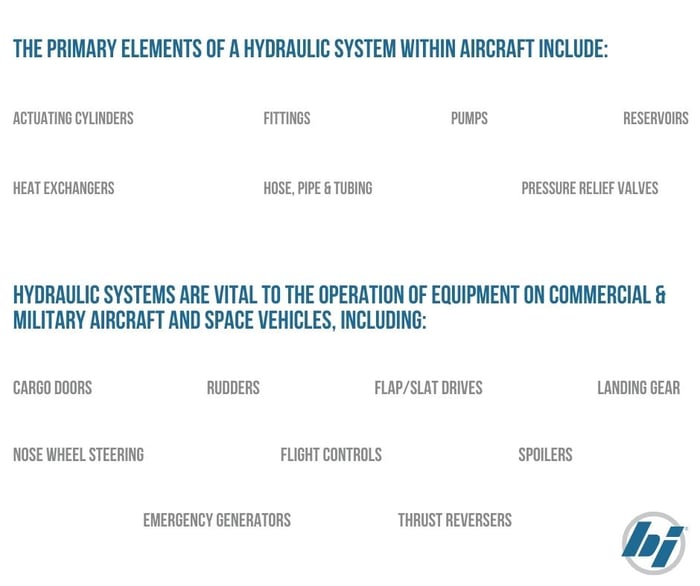

All segments in the aerospace industry use hydraulics-- from commercial and military aircraft, missiles and even the more recent phenomenon — space tourism. Hydraulic systems are used to operate and actuate landing gear, flaps and brakes. Larger aircrafts rely on hydraulics for flight controls, thrust reversers and spoilers on the upper surface of the wings.

Hydraulic systems are an integral part of aircraft design, transmitting very high pressures with a small volume of fluid. Hydraulic system pressures in military aircraft are much higher than most industrial applications and commercial planes. In most commercial aircraft, hydraulics run at 3,000 PSI, as opposed to military aircraft where operating pressures can run from 4,000 to 5,000 PSI, due to the need for light weight at higher altitudes and speeds. For example, the F-15 fighter jet can fly at a top speed of 3,017 mph, nearly five times that of a Boeing 747 at 660 mph.

Even spaceship engineer “Scotty” on Star Trek’s USS Enterprise knew the multitude of hydraulic fittings, valves and other components within an aircraft or rocket, although he may not have known they must all be compliant to ISO 9001:2015, AS9100D, NADCAP and ITAR/EAR. Thankfully, Brennan knows this and is compliant with industry standards.

Roller coasters, Ferris wheels, pendulum-type rides and any attraction that depends on heavy forces relies on hydraulic actuation. Hydraulic systems play a critical role in keeping rides safe. They are designed to withstand and release massive amounts of force with remarkable precision and ensure control of repetitive motion. Hydraulic systems are also used in safety devices, such as powering the automatic bars or harnesses that safely hold passengers in the seat by lowering and locking into position. Equipment and components frequently found on amusement park rides include:

- High performance hydraulic powered engines and brake lines

- Hydraulic lift systems

- Hydraulic power units, cylinders, valves and filter regulator lubricators

- Multiple hydraulic fitting and valve types

- Pneumatic push-to-connect fittings

Food and Beverage Industry

High pressures, extreme temperatures and equipment moving at high speeds are typical conditions in food and beverage plants. Hydraulic and pneumatic systems keep equipment running as they move ingredients from processing to final packaging and product loading. They are used in every part of the food and beverage supply chain, operating in harsh and extreme environments. A primary component in food and beverage conveyance systems is pneumatic cylinders, able to provide both linear and rotational motion.

Hydraulics and pneumatics facilitate many functions in the food and beverage industry, relying on fittings, adapters and valves made of 316 stainless steel or 316-Ti SS (316 titanium stainless steel), food grade plastic fittings and tubing to control:

- Mixers and blenders

- Processing systems that cut and slice

- Ingredient dispensers for liquid and solid food

- Conveyor systems for moving, sorting and distributing items to different areas of the plant

- Forklifts for carrying raw ingredients and finished products

- Blow-molding equipment for packaging

Medical and Pharmaceutical

The applications are wide and varying with equipment that uses hydraulics in operating tables and exam chairs, as well as chemical transfer systems in pharmaceutical manufacturing. Hydraulic seals in specifically designed medical applications are critical components in devices such as medical lasers, oxygenators, clinical blood pumps, respiratory systems, robotic surgical instruments and syringes. Plus, instrumentation components are also widely used in medical equipment and pharmaceutical manufacturing, particularly (instrumentation valves and) stainless steel double and single ferrule fittings.

Packaging Equipment

Packaging equipment uses hydraulic cylinders, adapters and pneumatic fittings for automated packaging-- from food products to nuts and bolts. They are often used in equipment to package products in different grades of polyethylene bags.

The packaging industry also relies heavily on hydraulic adapters and other components in conveyor systems, robotics, presses, palletizers, in addition to waste transfer and removal. Hot glue equipment is used to seal many types of packaging materials, such as corrugated cardboard and certain plastics. Due to extreme heat, Viton O-rings are required in fittings and glue heads that incorporate small size O-ring plugs and adapters.

Conclusion

Hydraulics are a vital part of our lives. From the adjustable desk chair you’re sitting in, to the car you’ll fill with gas on the way home. The next time you drink a beer at a brewery, visit an amusement park or take a vacation on an airplane, consider the hydraulic components allowing you to enjoy that experience.

Once again, the 4th industrial revolution is primarily driven by advancements in digital technology. However, a major part of that technology is used to operate mechanical devices — the hydraulics that power our world.

Sources Include:

.png)