Hydraulic fluid power is created as the pump pushes fluid through the system. The fluid is routed through valves that direct the flow and relieve pressure when required. The fluid actuates the cylinder, resulting in hydraulic energy converting into mechanical energy.

This begs the question: Does a hydraulic pump create pressure or flow?

A hydraulic pump has two jobs:

1. It generates mechanical action that creates a vacuum at the inlet, allowing atmospheric pressure to push hydraulic fluid from the reservoir to the inlet line.

2. The mechanical action forces the fluid from the pump outlet into the hydraulic system where the pump makes the liquid move, i.e., flow.

The pump does not generate the pressure, but provides the necessary flow of hydraulic fluid. The flow creates the pressure due to its resistance to the fluid flow in the system.

Don’t be confused: Flow is the rate at which pressure is created. However, it’s pressure that makes “it” go. “It” being the thing that’s acted upon to move. For instance, pressure makes a piston rod push or pull on the arm of a backhoe or extends and retracts the landing gear on aircraft.

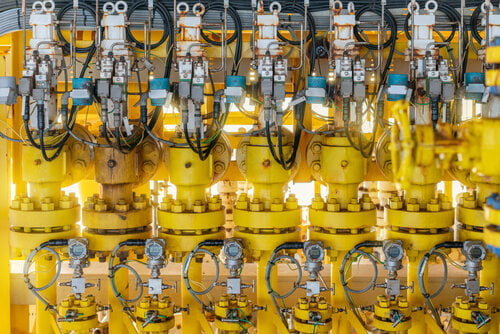

Hydraulic Flow Control Valves

There can be many flow control valves in a system regulating the flow in any given portion of a hydraulic circuit. Typical valves that regulate flow are:

- Ball valves

- Butterfly valves

- Diaphragm valves

- Gate valves

- Needle valves

- Plug valves

Valves control the rate of flow to cylinders and motors (i.e., hydraulic actuator,) which ultimately regulates the speed of these components. Additionally, hydraulic flow control valves regulate the rate of energy transferred at a given pressure, creating work. This is based on work, energy and power: the actuator force multiplied by distance traveled equals work done on the load. In other words, the energy being transferred is equal to the total work done. As the speed of the actuator determines the energy transfer rate, speed becomes the function of the flow rate. Again, it’s all about flow, not pressure.

It’s important to understand what is meant by flow rate because it can be measured in a few non-equivalent ways. The method of measurement influences the selection of the hydraulic flow control valves. The most common formulas for calculating mass flow rate and volumetric flow rate are:

1. Mass flow rate is the mass of a liquid substance passing per unit time and is calculated by multiplying the volume of the flow rate by the mass density of the fluid (ρ).

2. Volumetric flow rate is the volume of liquid flowing through a system per unit of time and is calculated by multiplying the flow velocity of the mass elements (v) by the cross-sectional area of the hose, tube, pipe or valve orifice (A).

Directional Hydraulic Control Valves

There are directional control valves which provide a different function, rather than regulating flow. Directional hydraulic control valves transfer energy to the proper location at the appropriate time.

They serve to keep fluid in standby mode to prevent flow in the system until it's required for performing the necessary work. When actuated, hydraulic directional control valves operate to perform the necessary function. Once the operation is completed, they will shift back to the neutral position.

In some cases, directional control valves can be used to achieve pressure and flow rate control by throttling the flow of fluid.

Conclusion

Hydraulics refers to the transmission of force and is not a means to randomly move fluid. When a force is pushing on a column of hydraulic fluid, it’s just like pushing on a steel rod. A liquid may be less compact than a solid rod, but they are both transmitting force.

It's a popular misconception that a hydraulic pump creates pressure in the system. However, the pump creates flow, not pressure. Pressure is created from its resistance to flow. The bottom line is without flow, there is no pressure. It’s not uncommon for an operator to comment their line doesn’t have enough pressure. In reality, the real issue is flow rate. Unfortunately, some people working with hydraulics use the two terms interchangeably. Knowing the difference between hydraulic flow and pressure, and how one drives the other, is key to attaining effective pump performance.

It's worth repeating: a hydraulic pump does not deliver pressure. It produces a flow rate of a given amount of liquid over a certain period of time to create work.

Sources Include:

.png)