JIC fittings are compression fittings that have parallel threads and a 37-degree flare seating surface, as specified by SAE J514 and ISO 8434-2. The JIC 37-degree fittings are compatible with SAE 37 fittings, making them easily interchangeable. 37-degree fittings are used in higher pressure applications. Comparatively, the SAE 45-degree fittings are used for low pressures, such as automotive, air conditioning and refrigeration.

The most common materials for JIC 37 hydraulic fittings are carbon steel and stainless steel. Their parallel threads seal on a metal-to-metal surface, and the flared tube surface can be reliably sealed and re-sealed, making field replacement easy.

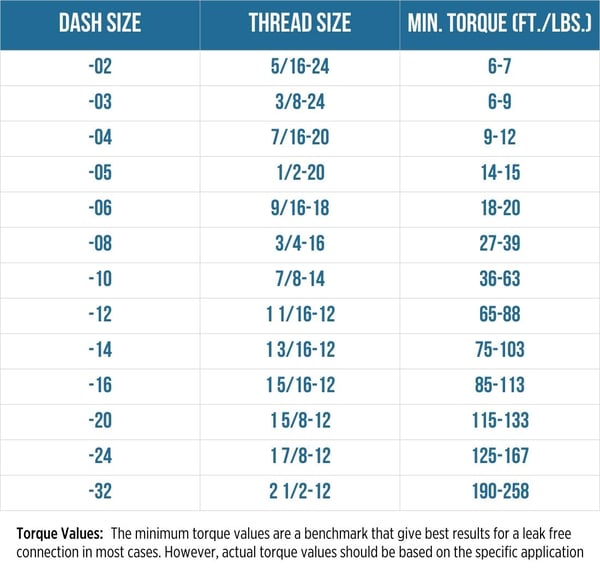

JIC is available in sizes ranging from -02 up to -40. A dash size is the determination for tube, hose and fitting measurements, measured in 1/16-inch increments. For instance, a -04 = a 4/16 or ¼ inch ID hose and a -32 = 32/16 or 2-inch ID hose.

Suggested JIC 37 Degree Fitting Assembly Instructions

- Lubricate the threads and cone with hydraulic fluid or light lubricating oil.

- Align mating components and turn flare nut by hand until sealing surfaces make contact.

- Torque the nut to the values shown in the table below. If there is a wrench pad next to the nut, place a second wrench on the pad to prevent the flare from rotating while it’s being torqued.

Wet Torquing

Wet torquing means lubricating the threads and O-ring (if applicable) of the fitting with hydraulic fluid before installation. However, the coefficient of friction can significantly vary due to differences in material, thickness, thread quality or plating types of different components.

Lubrication produces a more consistent coefficient of friction, increasing the clamping force on the sealing area and reducing the torque on threads. Over-tightening the connection causes threads to deform and lose their ability to sustain a sufficient clamping force on the seating surface. Severe conditions and/or prolonged operation can produce yielding that is likely to cause leaks. Wet torquing threads and O-rings (if applicable) is always recommended to maintain the quality and consistency of the connections.

Alternative Assembly Technique

If for any reason the torque method is not possible, you should still follow steps 1 through 3 above, then take these steps:

- Gently tighten the nut with a wrench until there is a firm resistance.

- Position a wrench next to the nut on the wrench pad, at/or near the 6:00 position.

- Put a second wrench on the nut, at/or near the 3:00 position.

- Turn the nut clockwise, 1/8 to 1/4 turn (do not exceed 1/4).

Note: Though following the steps above is a good rule of thumb, the required rotation typically decreases as the fitting size increases.

Torque Values for JIC 37 Degree Fittings

Over-tightening is likely the most common cause of a leaking JIC fitting. When over tightening, the mating seals bind to each other resulting in the leak. Follow these three steps to properly tighten and torque down JIC 37 fittings to avoid leaks:

- Tighten the nut by hand until it bottoms at the seat.

- Use a marker to draw a line lengthwise on the nut and extend it onto the adapter.

- Using a wrench, rotate the nut for torquing to the amount shown on the chart below:

- Farm Journal, Inc.

- Kingdaflex® Hose

FITTINGS 101: How to Identify JIC Fittings

.png)