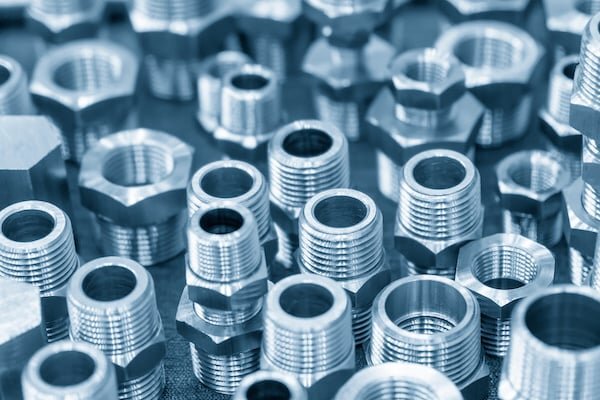

Experienced professionals recognize that the reliability of hydraulic systems hinges on the quality of their fittings. These fittings must endure high pressures and remain compatible with both the tube or hose and the media being transported within the system. Therefore, it's crucial to maintain hydraulic systems diligently. While issues like improper torquing or incorrectly sized fittings are easily identifiable and rectifiable, advanced troubleshooting demands a solid understanding of hydraulic systems and possible failures. This blog dives into troubleshooting techniques tailored for hydraulic component distributors.

Addressing micro leaks in high-pressure systems

One of the things to look out for when troubleshooting your system for failures is micro leaks. These leaks can be notoriously difficult to detect in systems operating under high pressure, as they only become apparent under specific conditions or temperatures.

To address the issue head on, try any one of the following:

- Leak detection kits, which use a fluorescent dye, emitting a purple or green glow under a black light to indicate the location of the leak.

- Ultrasonic leak detectors to identify high-frequence sounds generated by escaping fluids. However, their effectiveness can be hindered in extremely noisy environments, despite being designed to sense sounds within the 38 to 42 kHz range. Some acoustical leak testing devices are limited to specific frequency bands, potentially leading to false alarms or overlooking leaks altogether. Thus, they are most effective when operated by skilled personnel. These operators must isolate the sound frequency from background noise to accurately interpret environmental conditions.

Finding fitting failures due to pressure surge

Are you aware that sudden pressure spikes can lead to dynamic failures in hydraulic fittings, often unnoticed during regular operations? It's true. Monitoring your fittings becomes important with any fluctuations in pressure.

To do this, employ pressure transducers that use closed-loop feedback to monitor system pressure in real-time and identify spikes that may not be recorded during regular maintenance checks. Pressure transducers in hydraulic control systems can do the following:

- Ensure a heavy load doesn’t tip over a Bobcat or forklift.

- Control hydraulic pumps on oil rigs.

- Provide precise operation of aircraft landing gear.

That is why it’s important to ensure all your hydraulic components are rated for the maximum system pressure, including transient spikes and not just the operating pressure.

Preventing system contamination leading to abrasive wear

Contamination of hydraulic fluid can lead to premature wear and failure of hydraulic fittings, especially in systems requiring high precision and cleanliness. To combat this, it's essential to routinely inspect hydraulic fluid for the type and concentration of contaminants. Utilize a fluid filtration system tailored to your specific environment, as the size of contamination particles can vary.

Checking thermal expansion misalignment

Another critical concern to address during troubleshooting is checking thermal expansion misalignment. Temperature fluctuations can cause materials to expand or contract, resulting in misalignment of fittings and placing stress on hydraulic lines.

You can address this by installing metallic expansion joints or flexible fittings to accommodate heat-induced thermal expansion to prevent stress on connections. This will absorb any dimensional changes in hydraulic lines caused by expansion and contraction. Expansion components are essential in hydraulic systems that convey high-temperature substances, such as exhaust gases, steam or heated fluids. For critical applications, consider using fitting materials better suited for higher temperatures to provide a greater tolerance for thermal variance and conduct thermal cycle testing during maintenance periods.

Understanding electrochemical corrosion in mixed-metal systems

Using different metals in hydraulic systems can lead to galvanic corrosion, which deteriorates metal at the point of contact. The reason why this is important for you to understand is that the process weakens the structural integrity of metals and can result in leaks or failure of hydraulic fittings.

The solution for this is to ensure material compatibility in fittings, especially in systems where an electrolytic potential can occur. To minimize potential incompatibility, use non-conductive fittings or coatings to isolate metals from each other or select metals close together on the galvanic series, which defines their electrochemical potential.

Preventing improper residual stress from over-tightening

Even experienced technicians can inadvertently introduce residual stresses through over-tightening. The stress at the threaded or bolted joints can lead to corrosion, cracking or failure. These issues can compromise the integrity of your hydraulic fittings and pose serious safety risks.

A way to help prevent this is to utilize torque calibration and thread lubrication to ensure consistent and correct torque application. Additionally, consider utilizing torque angle methods to reduce the coefficient of friction where applicable, providing a more accurate indication of thread stretch and load.

Conclusion

Addressing hydraulic fitting issues requires more than just routine maintenance checks. You must understand the dynamics of the hydraulic system, material science and fluid mechanics. By utilizing advanced diagnostic tools and going into the inner workings of the system, you can increase the reliability and performance of your equipment. It’s not just about resolving issues at the end of the day; rather, it’s about having enough insight to strategically implement a plan for a proactive approach.

To learn more about proper hydraulic maintenance in your manufacturing equipment, check out our BluPrint.

.png)