Hydraulics have many uses; from mechanical systems which lift or push heavy objects, to landing gear in an aircraft for moving the wheels into place for cushioning the landing, to operating the bucket on a backhoe. And hydraulic hoses perform a vast number of critical functions in any system, from low to medium to high pressure applications, hoses are the arteries of a hydraulic system.

Color Coding: In Circuit Design & Laylines

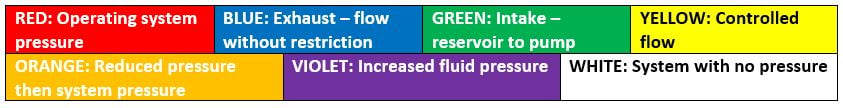

To provide engineers in the design of hydraulic systems a color coding standard is used in hydraulic circuit schematics. This does not apply to the hose itself. The same hose can used within a hydraulic circuit or system for multiple requirements within the circuit. However, for the standards used in a hydraulic circuit design the chart below illustrates how color codes can be used. This standardized color coding of flows and pressures was established by the Joint Industry Conference (JIC) and American National Standards Institute (ANSI).

With regard to color coding laylines of hose, according to an article in Hydraulics & Pneumatics many hose manufacturers responding to market trends for higher-pressure hoses have developed families of constant pressure hoses. These hoses meet or exceed ISO 18752 specifications, and each constant working pressure family of hose has color-coded laylines based on specific pressure ratings and are available with different colored cover options to match the application requirements. These hoses meet the minimum ISO 18752 Grade D, Type DC requirements of one million cycles and often exceed specification by being tested up to 2 million impulse cycles at a tighter bend radius than required by the specification. For example, one manufacturer supplies 1,000, 3,000, 4,000, 5,000, and 6,000 PSI hoses with different cover options, which are matched to the specific working pressures for providing cohesive hose and fitting systems. While SAE J517 and ISO 18752 do not require pressure impulse testing while the hose is moving, some of these manufacturers do conduct these tests to ensure extended service life of the hose.

Hydraulic hoses meeting ISO 18752 are specified by specific performance definitions which identify the grade and type of hose required for different applications based specific criteria including temperature, cycle ratings or impulse pressure.

Hydraulic Fitting Ferrules & Skiving

One-Piece Hose Fittings: One-piece hose fittings have a ferrule that is pre-crimped onto the hose fitting. The advantage being that the collar will not slip out of alignment. This style also ensures the correct ferrule is matched to the correct hydraulic hose fitting type. One-piece hose fittings are popular for maintenance in the field and good for basic applications and quick assembly.

Two-Piece Hose Fittings: The ferrule used with two-piece fittings allows greater flexibility in hose selection and connection, including 1SN, 2SN and multi-spiral hoses which allow for multiple two-piece fitting and ferrule options to accommodate the specific application. Two-piece hose fittings consist of an outer ferrule and an inner serrated hose stem, and are typically used in high pressure applications, particularly when there is the possibility of extreme hose vibration and/or pressure surges.

It's important to note to not mix and match fitting components from different manufacturers. The ferrule and hose tail must be compatible and come from the same manufacturer, otherwise it leaves fabricators and users open to a higher chance of failure and greater liability.

There are also two types of hydraulic hose ferrules.

- Skive ferrules have rounded serrations or teeth that bite into the wire braiding of the hose once the outer cover has been removed (skived).

- Non-skive ferrules have sharp serrations that bite through the hose cover.

Skiving: The procedure for skiving is to remove the outer cover at the end of a hydraulic hose where the ferrule will be installed, barely exposing the wire braid internal to the hose. Though some will use razor knives or hacksaws, the only proper way to perform skiving is by using skiving machines which have tooling that uses rotating mandrels to cut into the cover of the hose at a predetermined depth and length of the OD. This partially exposes the internal wire braid to accommodate the outer ferrule. Most high-pressure applications require the inner ID of the hose be skived to allow better seating of the internal hosetail fitting and provide a more secure connection.

Non Skiving: A hose is not skived when a one-piece fitting connection is used, ready to assemble without requiring the skiving process and therefore the cover is not removed from the hose. When using a one-piece fitting the thread of the ferrule is forced into the hose cover, biting into the rubber. In some applications this can result in a less reliable connection where the fitting may become loose and leak around the connection.

.png)