In the aerospace industry, O-rings are very popular among equipment designers because of their leak-tight connections, typically using a 90 durometer, Buna-N (Nitrile) O-ring. There are two primary types of O-ring boss fittings:

In the aerospace industry, O-rings are very popular among equipment designers because of their leak-tight connections, typically using a 90 durometer, Buna-N (Nitrile) O-ring. There are two primary types of O-ring boss fittings:

1) SAE STRAIGHT-THREAD O-RING BOSS FITTINGS

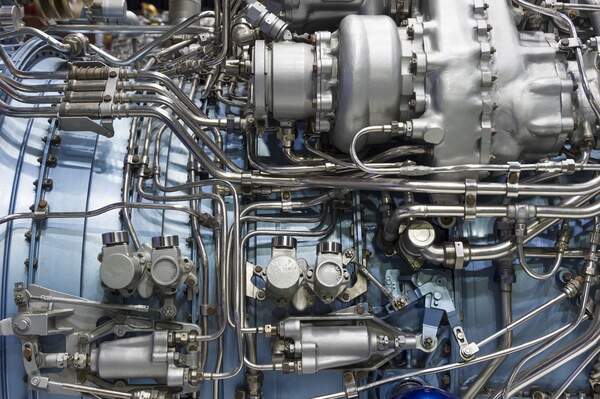

These fittings incorporate a port connection as recommended by the National Fire Protection Association (N.F.P.A.) for leak prevention in medium and high pressure hydraulic systems. The male connection is a straight thread with an O-ring. The female port has a straight thread and a machined surface to provide a smooth, flat, accurately located surface (minimum spotface), along with a chamfer where the O-ring seats. It seals when the O-ring is compressed into the chamfer when mating the male connection. The O-ring in an O-ring boss fitting seats between the threads and wrench flats, and is positioned around the OD of the male end of the fitting. This allows for a leak-tight seal which is seated against the female port. O-ring boss fittings are either adjustable or non-adjustable. Adjustable O-ring fittings are typically elbows or tees that are installed in a fixed direction. Non-adjustable O-ring fittings are usually plugs and basic connectors that are fitted into a port without the need for alignment.

2) FACE SEAL OR FLAT-FACE O-RING (FFOR) FITTINGS

Face seal and flat-face O-ring connections are considered the best for leak control. The male connector has a straight thread and an O-ring in the face. The female has a straight thread and a machined flat face. The seal takes place by compressing the O-ring onto the flat face of the female, similar to the split flange type fitting. The threads maintain the connection mechanically.

Choosing O-ring boss fittings or FFOR fittings often depends on the location for wrench clearance. However, flange fittings are mostly used with applications calling for ≥ 7/8” OD tubing or extremely high pressures.

This blog is an excerpt from our Aerospace Whitepaper, if you would like to learn more, click below!