Push-to-Connect fittings are typically made of a glass reinforced thermoplastic or nickel-plated brass. They are commonly used with polyurethane or nylon tubing. However, some applications using brass Push-to-Connect may call for brass tubing and provide excellent leak-free and secure connections for gas, air or liquid flow line pneumatic applications. They are available in both Imperial and Metric sizes. Additionally, stainless steel Push-to-Connect fittings are used in special applications requiring increased durability, while providing good corrosion

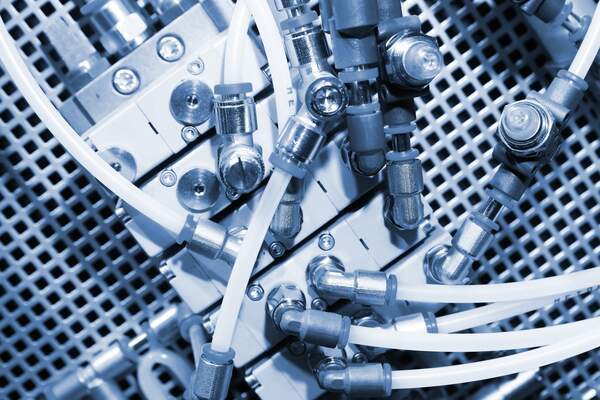

Push-to-Connect fittings are typically made of a glass reinforced thermoplastic or nickel-plated brass. They are commonly used with polyurethane or nylon tubing. However, some applications using brass Push-to-Connect may call for brass tubing and provide excellent leak-free and secure connections for gas, air or liquid flow applications. They are available in both Imperial and Metric sizes. Additionally, stainless steel Push-to-Connect fittings are used in special applications requiring increased durability, while providing good corrosion resistance.

Different Materials

There are two types of push-to-connect fitting materials commonly used; composite and brass.

Composite

The development of composite body push-to-connect fittings has provided a significant advancement over their brass counterpart. Though brass is still a common material, the polymer body and brass screw threads in a composite fitting are extremely durable and provide labor- savings, lighter weight and lower cost compared to brass push-to-connect fittings.

Foundation brakes are the most common air brake systems in trucks and buses. They use a triple-valve principle which charges air into the tank, applying the brakes, and releasing them. Pressure increases in the cylinder while applying the brakes and in turn decreases pressure in the reservoir. The majority of the vehicles with air brakes have a graduated release system which allows a partial increase in pressure that delivers a proportional release in the brakes.

For the safety of our roadways, air brakes are the most important component of commercial motor vehicles. The braking system on semi-trucks, large straight trucks, garbage trucks and school buses use compressed air to push the brake shoe lining onto the brake drum creating friction to slow the vehicle. That may not seem very complicated, but it is. The system to slow down a vehicle that may weigh 80,000 pounds fully loaded is not only complicated, it’s critical. Air brakes have to work effectively every time and they must be adequately maintained.

- Remove burrs on the end of the pipe which can cut into the O-ring and make slight serrations where the push in fitting collar will slide on to allow for an adequate grip.

- Ensure that the Push to Connect fittings are recommended and approved for the application.

Push to Connect fittings are much easier to use compared to compression fittings. And they are more practical than permanent solvent-gluing CPVC and PVC pipes or sweat-soldering brass pipes with a torch in general plumbing applications. These fittings have proven to provide highly reliable connections even when they are hidden behind panels or other enclosed areas. When making joints for new installation or repair using brass tube, PEX or CPVC, Push to Connect fittings are the easiest and fastest method to provide an air or fluid tight seal when the tube or pipe is inserted.

Let’s focus on Push to Connect fittings. They are available in different materials and are selected based on the application and tube material. These fittings are typically made of:

- Aluminum

- Brass

- Stainless steel

- Composite

- Nickel-plated Brass

- Plastic polymer

- Brass PEX (Cross-linked polyethylene)

Fast and Repeatable

Push to Connect couplings allow for a fast and easy way to repeatedly connect and disconnect air or fluid lines. If a tube or hose in a fluid or air system needs to be disconnected and reconnected on a frequent basis the best solution is a Push to Connect fitting. It will improve productivity, ensure a properly sealed connection and eliminate downtime.

Applications & Benefits of Push to Connect Fittings

Most of us have never had this happen. Many years ago I was pulling away from the gas pump and I heard a pop-bang noise and then the sound of scraping as though I was pulling something. I jumped out of my car to find the gas hose lying on the ground sticking out of my car. I started to panic. I looked at the pump expecting gas to be shooting out at high pressure. Surely the entire gas station was about to explode. But nothing happened. Still freaked out that I broke it, I went inside. With obvious fear in my voice I explained what happened to the woman behind the counter. She laughed and said not to worry about it.

Categories

- Fittings (55)

- Company Updates (45)

- Aerospace (26)

- Hydraulic Maintenance (23)

- Instrumentation (18)

- Helpful Info (14)

- Industry News (14)

- Supply Chain (14)

- Tradeshows (13)

- Distributed Manufacturing (11)

- Flange Fittings (11)

- Hose Fittings (10)

- Push To Connect (10)

- Hydraulic Safety (9)

- Technology (9)

- Tube Fittings (9)

- DIN (6)

- O-Ring Face Seal Fittings (6)

- Thread Identification & Measurement (6)

- D.O.T. (5)

- News (5)

- Value Through Strength (5)

- Announcements (4)

- Distributors (4)

- Fragmentation (4)

- Literature (4)

- ORING (4)

- Specialty Alloys (4)

- Acquisitions (3)

- Forged Fittings (3)

- Giving Back (3)

- Agriculture (2)

- Brennan Value (2)

- Contamination (2)

- Brennan University (1)

- Crimp Oil (1)

- Events (1)

- Industrial Marketing (1)

- Oil and Gas (1)

- Truck and Trailer (1)

Recent Posts

Subscribe to Blog Notifications

Keep up to date with the latest from the Brennan Blog by subscribing to blog notifications below. Every month we will send you a brief digest of the latest posts with a link where you can read more.